Why Conduct An Electrical Infrared Thermographic Inspection?

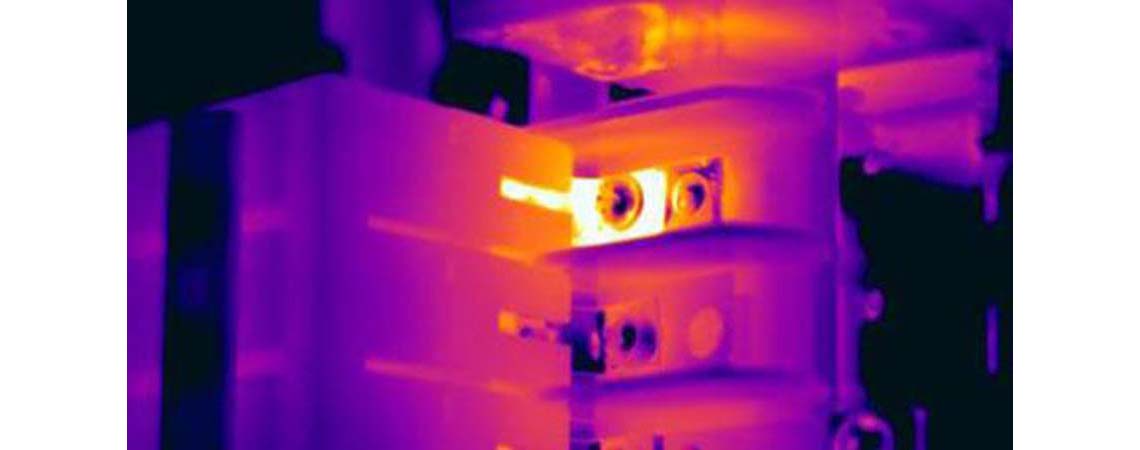

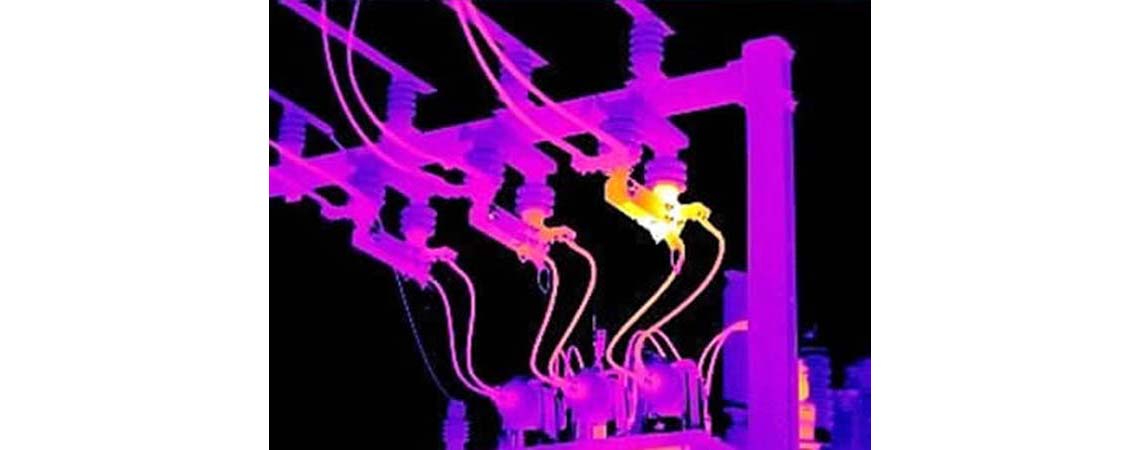

Heat emitted from an electrical component is directly related to electrical current and resistance. Increased resistance could be a direct result of a loose or corroded connection, a manufacturer’s defect, and/or failing equipment, etc. Utilizing an infrared camera to inspect electrical components allows for detection of hot spots or problem areas prior to catastrophic failure. Catastrophic failures can cause damage to clients equipment and building structures resulting in production downtime and costly insurance claims. In some cases, these failures can even result in personal injury and/or death to individuals working in or around the effected areas.

How Is An Electrical Infrared Thermographic Inspection Completed?

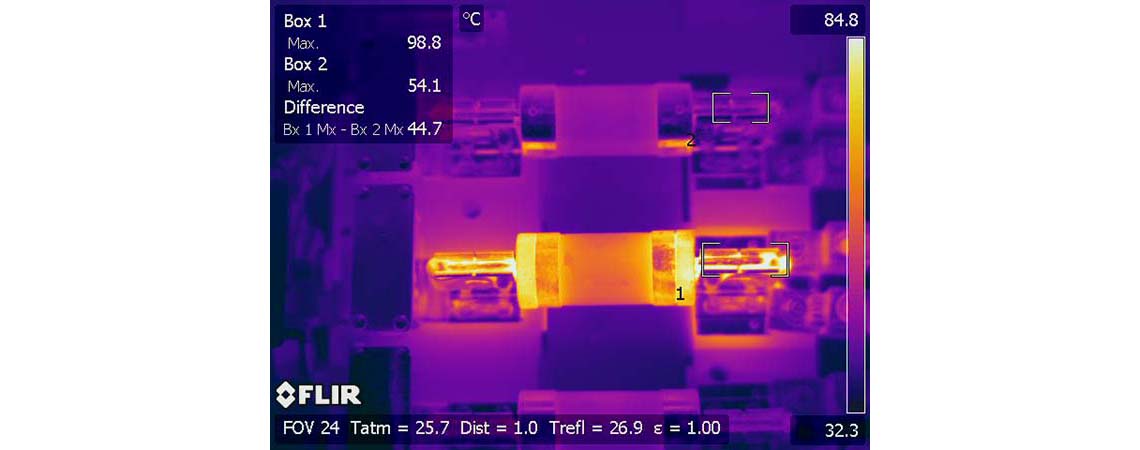

Because thermography is non-contact and non-destructive, there is no need to interrupt production or plan for costly shutdowns. Our thermographers inspect your equipment using industry leading FLIR infrared equipment under normal loads and operating conditions so you don’t have to disrupt your service and production schedules. The inspection process is completed in an efficient manner, but to ensure an accurate assessment, all covers must be removed when possible. An exception to this would be inspecting equipment that is equipped with special infrared viewing windows. This allows an inspection without the need to remove the cover. By performing an infrared scan of your electrical system in ‘real time’, our inspections can help you understand the practical impacts of emerging component problems. Common problems which are identified as a result of this inspection are loose connections, corrosion, faulty or overloaded breakers, imbalanced loads, and so much more.

Electrical Infrared Inspections are performed on but not limited to the following equipment:

- Electrical Panels & CDP’S

- MCC’s

- Disconnects

- Transformers

- Switchgear

- Buss Ducts

- Starters

- Splitters

- Splices

- Junction Boxes

- Solar Panels

- Transmission Lines

- Substations

- High Voltage Cables / Terminations

How Can I View The Results From The Inspection?

All inspections are followed with a comprehensive report including but not limited to:

- A detailed equipment list of all equipment inspected

- A detailed report of all problem areas

- Both an infrared image as well as a conventional digital image of the problem area identified

- All reports will be compiled in a professional report and delivered via email to stay green and help save the environment. For those clients that wish to have a hard copy delivered, one copy of the report will be included complimentary in the cost of the inspection.

- Next day report delivery guaranteed to all our clients via email if requested