Why Conduct A Mechanical Infrared Thermographic Inspection?

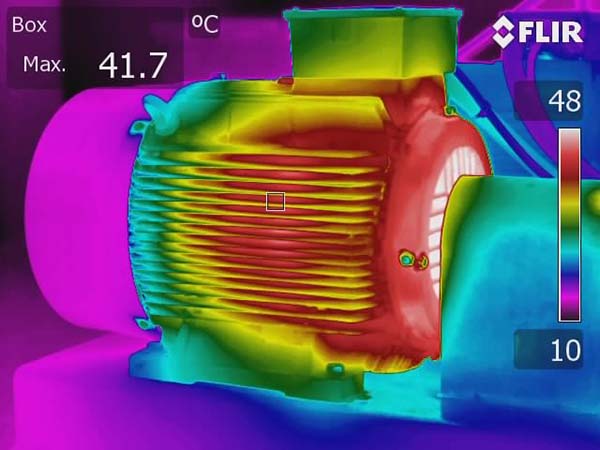

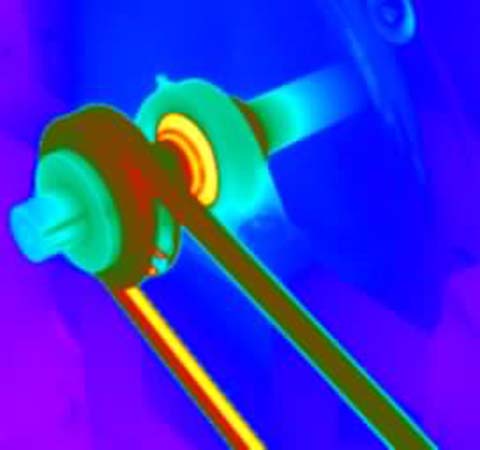

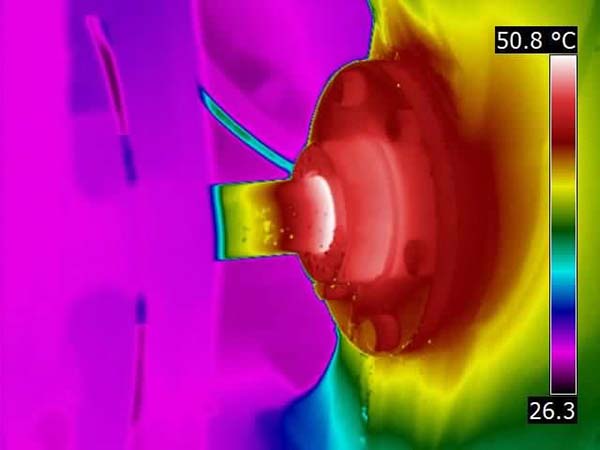

In mechanical systems, excessive heat is a sign of impending trouble. High temperatures indicate excessive electrical resistance, worn components, lubrication failure, or other common problems that can lead to expensive or even catastrophic failures. Trying to find these failures with visual and manual inspections is a costly, time-consuming process that may not locate the underlying problems. Common problems which are identified as a result of this inspection are overheating motors, bearings, couplings, shafts, belts, u-joints caused by miss-alignment, overloading, lack of lubrication and more.

Mechanical Infrared Inspections are performed on but not limited to the following equipment:

- Electric Motors

- Bearings

- HVAC Equipment

- Furnaces

- Chillers

- Boilers

- Generators

- Engines

- Steam Traps and/or Valves

How Can I View The Results From The Inspection?

All inspections are followed with a comprehensive report including but not limited to:

- A detailed equipment list of all equipment inspected

- A detailed report of all problem areas

- Both an infrared image as well as a conventional digital image of the problem area identified

- All reports will be compiled in a professional report and delivered via email to stay green and help save the environment. For those clients that wish to have a hard copy delivered, one copy of the report will be included complimentary in the cost of the inspection.

- Next day report delivery guaranteed to all our clients via email if requested